In our own production facility in Temse (Insulcon N.V. Belgium) we produce high temperature textile products. This includes a wide range of custom-made insulation and sealing materials. Different types of raw materials are being used (glass fibres, low bio-persistent, silica, ceramic fibres, etc.) to be able to supply our customers with a complete range of products.

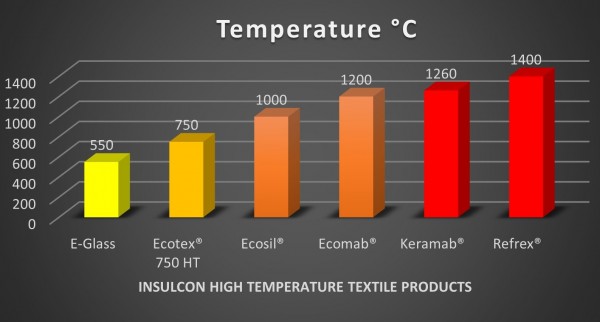

Worldwide our high temperature textile products (E-Glass, Vitrolux, HT-Glass (Ecotex®750 HT), Ecomab®, Ecosil and Keramab®) are applied as door seals in boilers, ovens and reformers, seals between filter elements, seals for continuous casting, insulation of gas and steam turbines, kiln car seals, etc. All these products are manufactured on our highly advanced installation which is one of the largest of its kind in Europe.

Our textile products are available in several product forms, such as mentioned below.

As alternative for ceramic fibre textiles (Keramab®) we can supply textiles made out of Ecomab® low bio persistent yarns. Ecomab® products are not classified under directive GHS/CLP (Nota Q). Therefore, labelling and special precautions during processing and packaging are not required.

Depending on specific needs, textile products can be manufactured to your liking. For example, braided packings can be supplied in round, square or rectangular sections. Some variations can be impregnated with PTFE, graphite or other special coatings.

Door seals in (domestic) boilers, ovens and stoves

Steam tracing lines

Tadpole gaskets

Furnace door gaskets

Pipe and boiler lagging

Personnel protection

Which variations? Braided packings can be supplied in round, square and rectangular sections by braiding several types of yarn...

Read more

Product description Ecomab® textile products are unique, high temperature, low bio-persistent, textile products that are...

Read more

DescriptionEcosil® silica products are unique, high temperature textile products that can be custom-made in our own production...

Read more

Technical Fabrics and tapes are woven with selvedges in several widths. Depending on the weave pattern, which is used and the...

Read more

Keramab® and Ecomab® fibre ropes and joints are sealing products composed of a soft core with an over braiding (open or closed...

Read more

The Golden Super® Rope is a unique high temperature and mechanical resistant seal. Due to its high density, the Golden Super...

Read more

Insulcon N.V. manufactures a wide range of industrial textiles since 1905. Using different types of raw materials such as...

Read more

Sleeves are produced by knitting or braiding several types of yarn into a hollow sleeve.

Our sleeves are available in the...

Twisted ropes are produced from a number of yarns, twisted together. The diameter of the rope is determined by the number and...

Read more

Insulcon’s Ultimate Ring Seals (URS) are uniquely strong endless textile ring seals, that are specially designed for high...

Read more

In addition to our well known program High Temperature Textile Products, we recently introduced a new textile product to our...

Read more

Looking for advice? We will help you to find a suitable solution! Give us your details and we will contact you as soon as possible.